* Inverter soft-switching conversion technology, small size, light weight, energy saving (compared with thyristor rectifier welder saving 30% -40%), EMI and efficient design, the power grid pollution.

* Internal structure of the modular design, complete protection, and the use of pure IGBT devices, machine safety and reliability, low failure rate, without professional, general electrical maintenance, maintenance.

* Board waterproof, corrosion, moisture, dust treatment, especially for: field operations, tunnels, high-rise buildings and other humidity, harsh environment engineering.

* Stepless welding current, welding time, digital display welding parameters and input voltage, input voltage detection display is "prone" welder specific. Welder without grid voltage meter to understand the situation, convenient and practical.

* Fan dormancy type of work, energy saving, reducing dust within the organization, life expectancy is three times higher.

* Mains voltage compensation function, when the lower voltage, the device can automatically stabilize the welding parameters, when the ultra-low voltage of this equipment can still be normal welding <only the maximum current slight decline> welding power much higher than ordinary welder. The special characteristics apply to: Electricity shortages and requiring multiple devices at the same construction project <such as: generator power engineering, shipbuilding, steel and other>

* Welding time, manual and automatic control of any conversion, adapt to a variety of welding processes.

* Welding parameter is set fully in the panel, truly fool-type devices.

* Reasonable output voltage design, torch cable extended use. Sustained high load, high fatigue strength.

* Book a SMAW, carbon arc gouging.

* Special torch structure and large power circuit to enhance welding torch, heat a small, durable, automatic completion of the welding process. 20 minutes to learn ordinary welder operation, one hour that is skilled welding.

* High-strength steel electrostatic spraying, chassis, strong corrosion resistance.

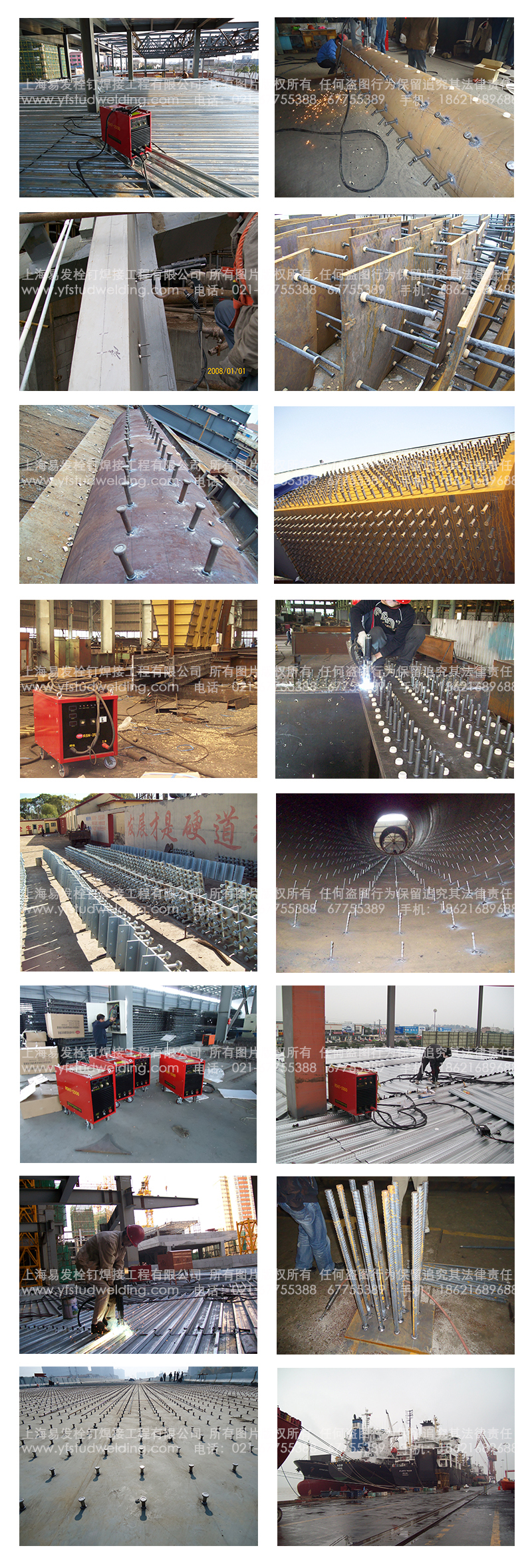

Dedicated to: furnaces, boilers, shipbuilding, power plant construction, chemical construction, mechanical equipment, all kinds of pipes, tanks, barrel, vehicle manufacturing. Thickness ≥3mm above, similar tack welding M4mm-M20mm screws, studs, pins, shaped nails, corrugated nails, anchors, etc., suppositories. Welding materials: carbon steel, low alloy steel, copper and so has the arc weldability material. In the surface oxide layer, the film, primer or plating treatment on the workpiece by welding. After welding deformation, no convex marks, welding, vertical welding, overhead welding, full welding.